Amar Found into a leading company and build up the sustainable design and construction to our clients.

Amar Found is the recognized leader in providing Rock and Soil anchoring solution to the civil engineering and construction markets. Soil Anchoring service is used for designing of slope stability analysis and education work.

Anchor heads are made of forged steel, with shape and dimensions allowing a uniform stress distribution on the structure, and a correct housing of the anchorages and wedge system and of the eventual protection cap of the anchor head system.

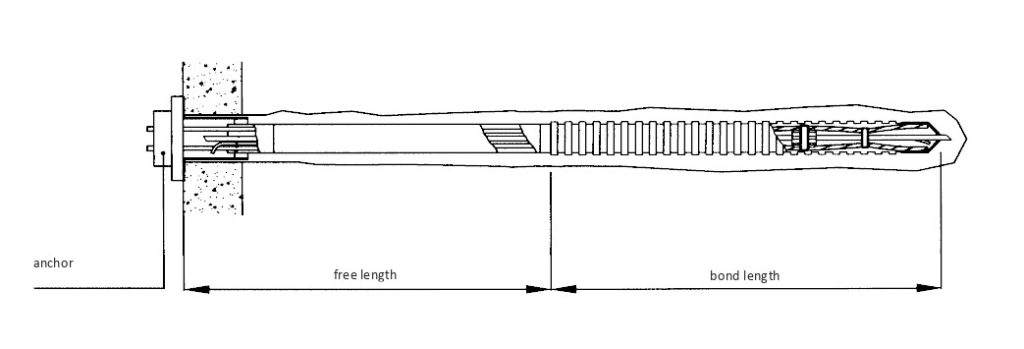

It represents, in the length, the part of the anchor between the bond and the anchor head, in which the tension element undergoes its lengthening during tensioning operations; in this zone strands are protected in a sheath, having also the purpose to protect them against corrosion and stray currents.

This is the part of the anchor transmitting the tensile stresses to the ground by means of cement grout, assuring adherence between the tension elements and the borehole. To increase their cement-steel adherence, strands are suitably shaped, by means of spacers, in a sinusoidal form with loops and knots. To make easier the anchor insertion into the borehole, its head is connected to an ogive, shaped to overcome the friction of the hole outline during threading phase.

The calculation can be:

Parameters to be fixed are:

Depending on its length in the time and on the environmental aggressiveness, anchors can be classified as:

when they are applied to temporary structures to contrast the forces that arise during the structure erection, but that are no longer present when the work is finished.

when their action is requested for an important period in the life of the structure to which they are applied: in this case, anchor protection must be total.

In cohesive soils it’s important to increase frictions between grouting of the ground anchor’s body and the surrounding soil; in this case grouting is

performed by means of pipes with valves, equipped with machetes placed at variable distance depending on soil characteristics (30, 50, 100 cm.), with the aim to have the possibility to make localized pressure grouting operations, also in different phases, and eventually to repeat grouting after tensioning, in case of lack of adherence with the soil.

This kind of anchor is mainly required for temporary use (construction of diaphragms, bulkheads, etc.) and for use in non-aggressive soils.

According to the foreseen type of grouting, anchors can be supplied either with normal HDPE pipes or with pipes equipped with “manchette” valves for repeated

grouting.